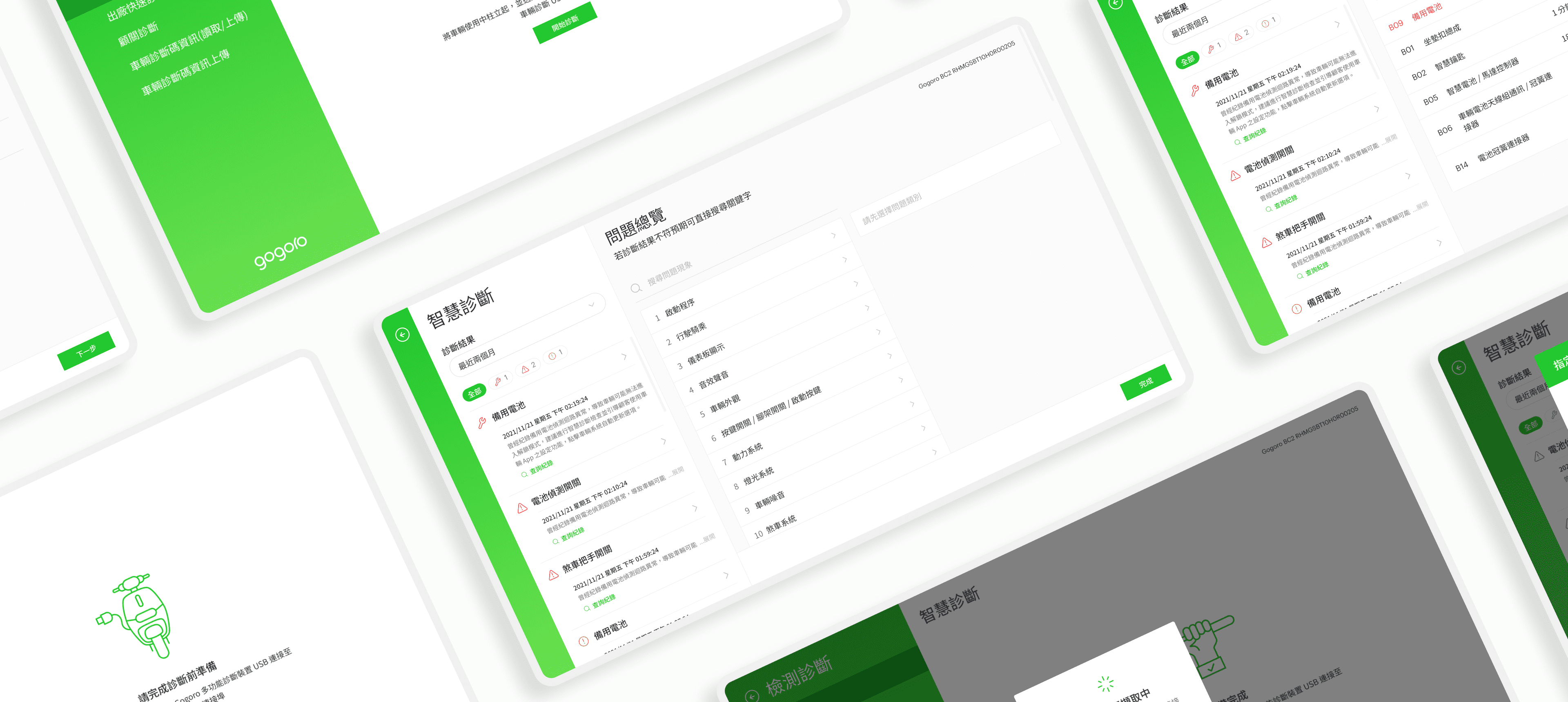

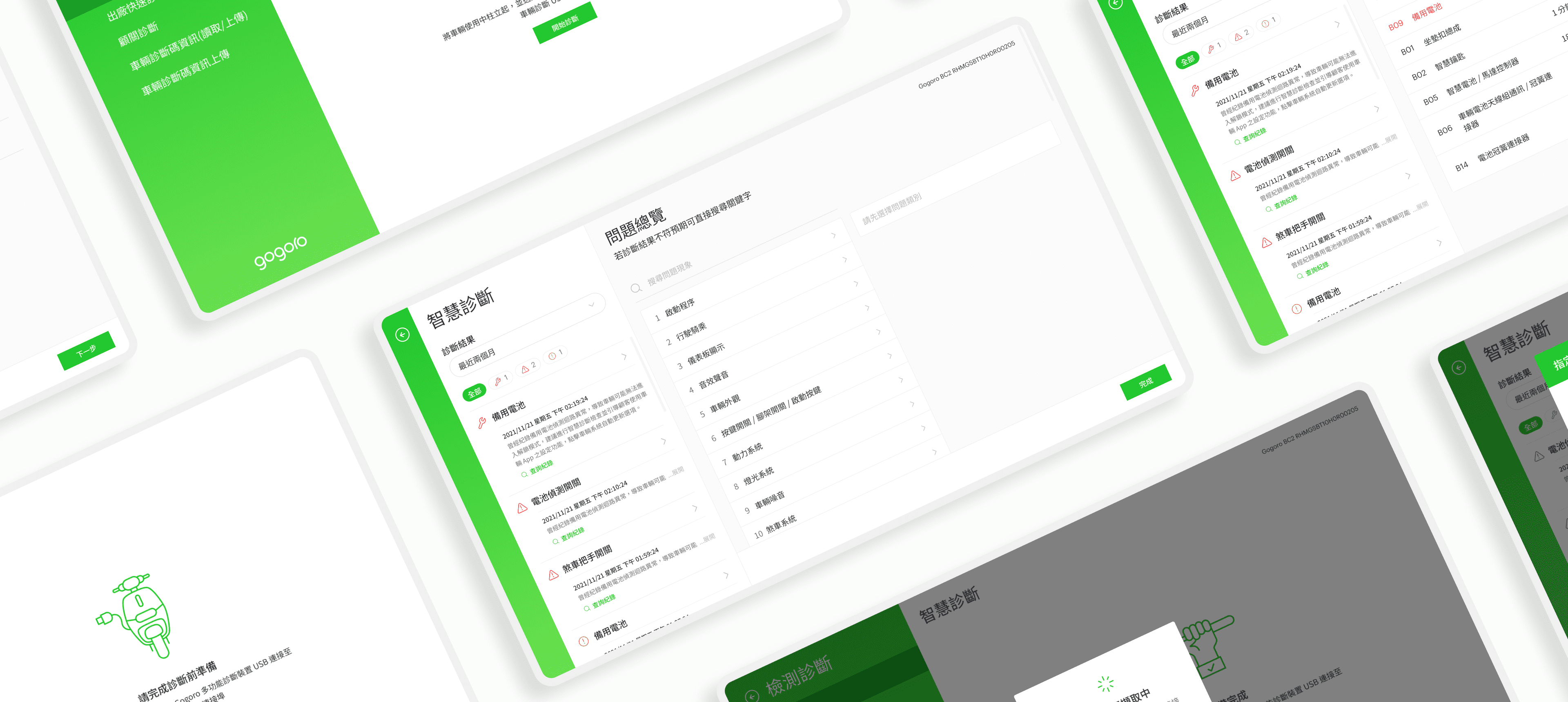

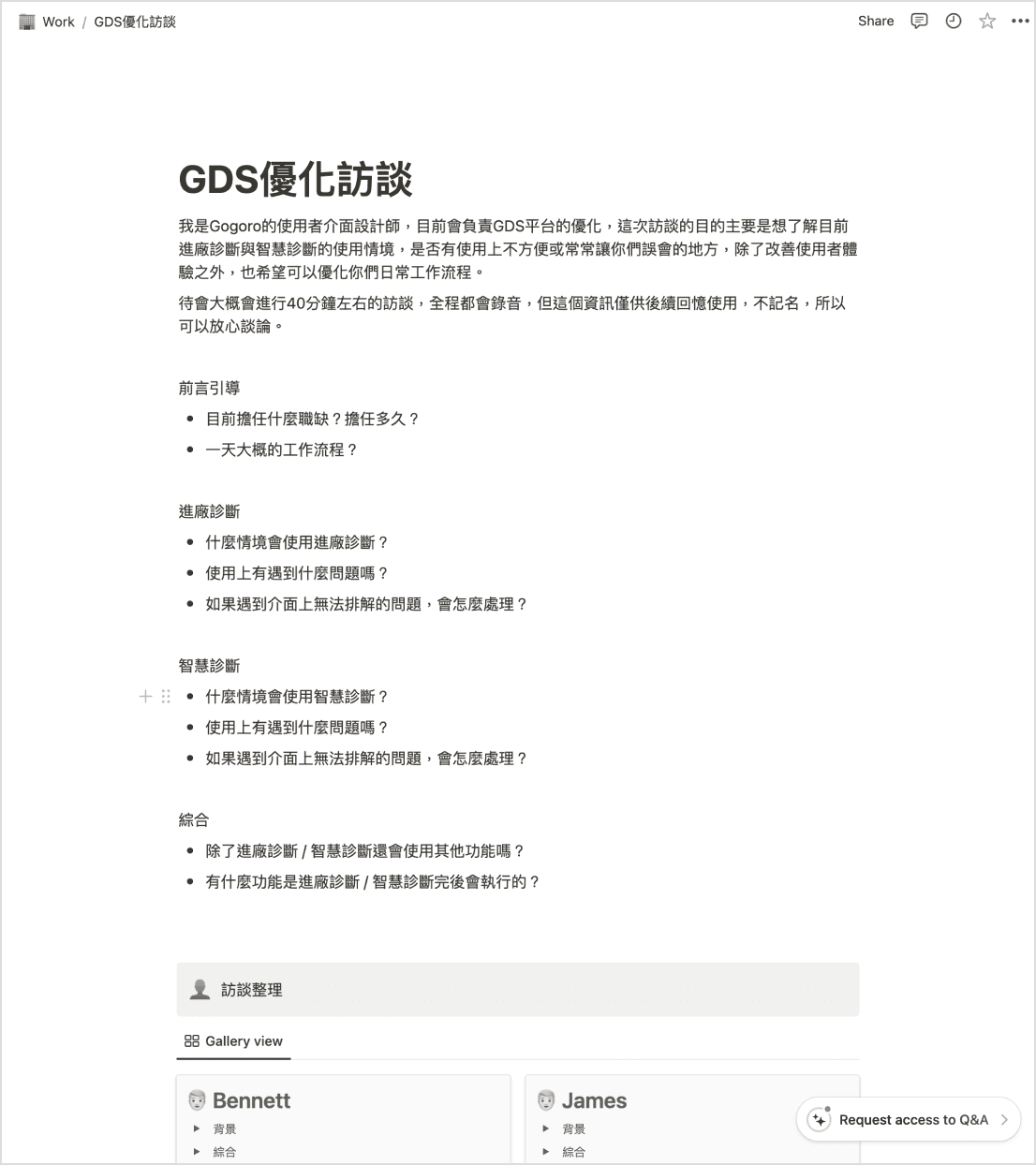

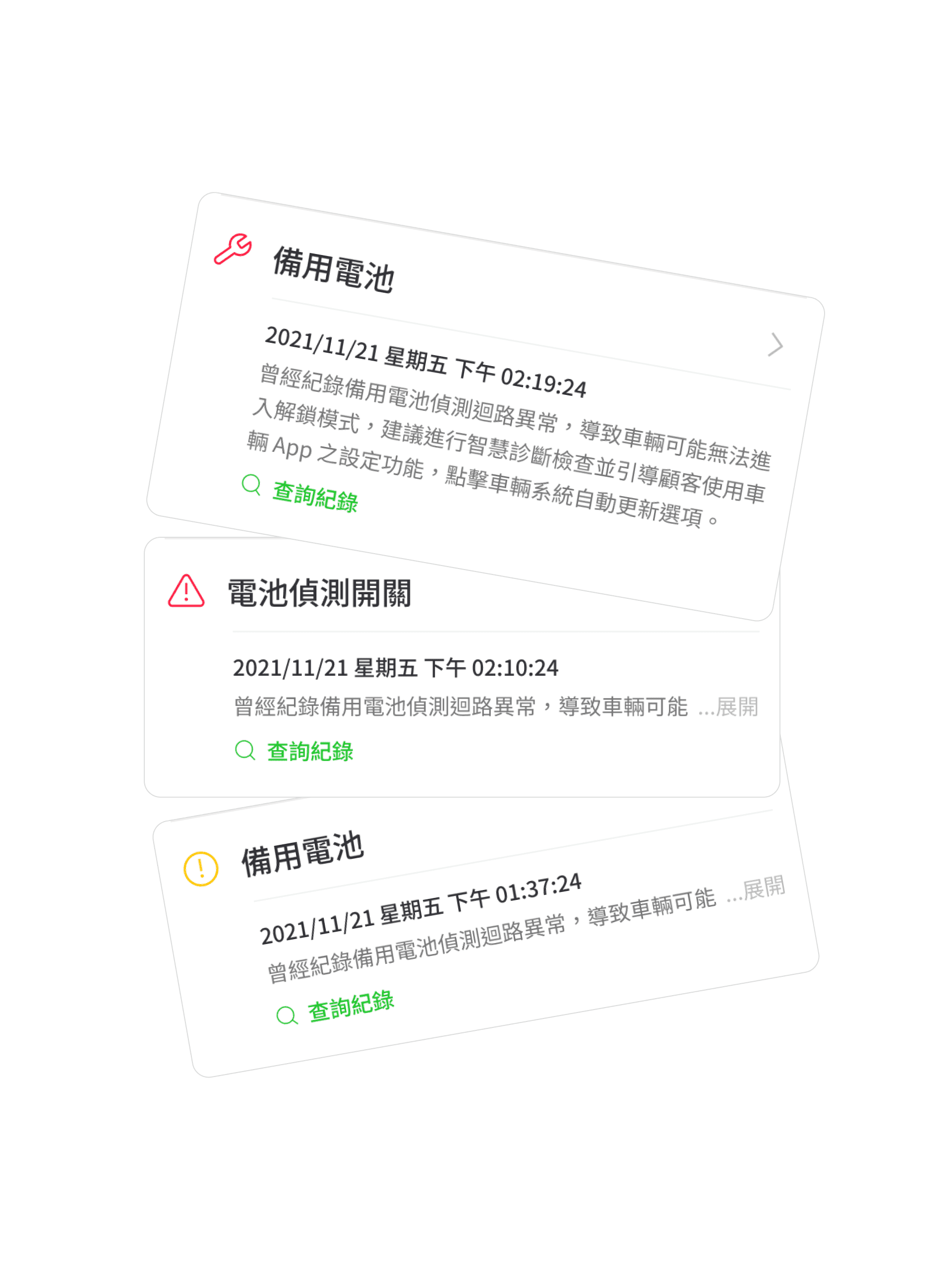

Gogoro Diagnostic System, or GDS for short, is a system used by Gogoro maintenance technicians to detect and diagnose whether the electronic control components of their own scooters are normal.

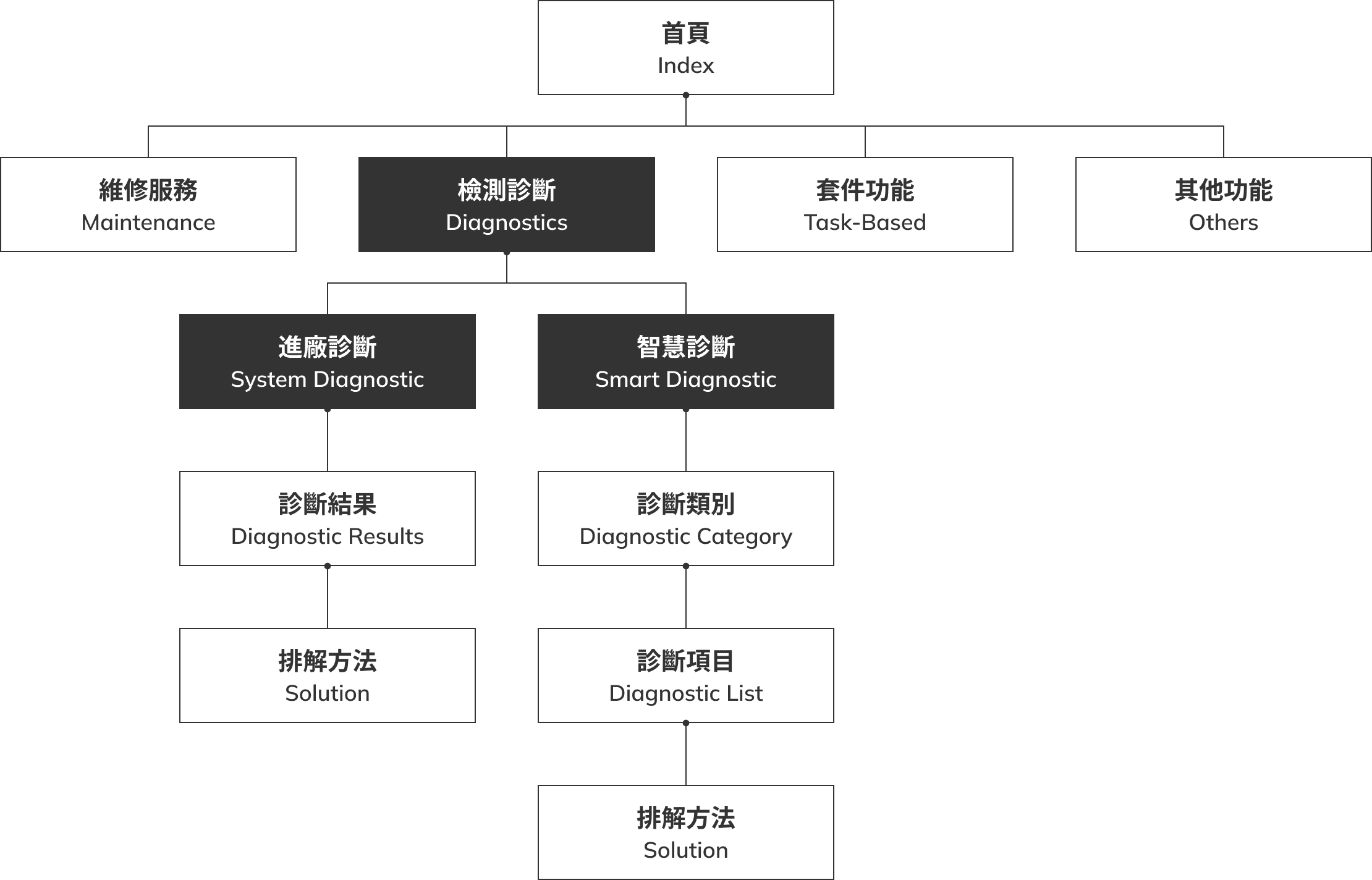

Since we often received feedback from scooter owners that repairs and maintenance did not solve the problems initially discovered, the company believed that the problem was caused by the failure of front-line maintenance technicians to follow the SOP for maintenance.

GDS is an application designed in the early stages of Gogoro's founding.

The interface style is relatively old, so the initial optimization direction of the project will not only adjust the process to reduce breakpoints, but also improve the readability of the old interface.

-

Role

UI/UX Designer

-

Duration

3 months

-

Team

1 Manual Writer, 1 PM, 1 Designer, 1 Developer